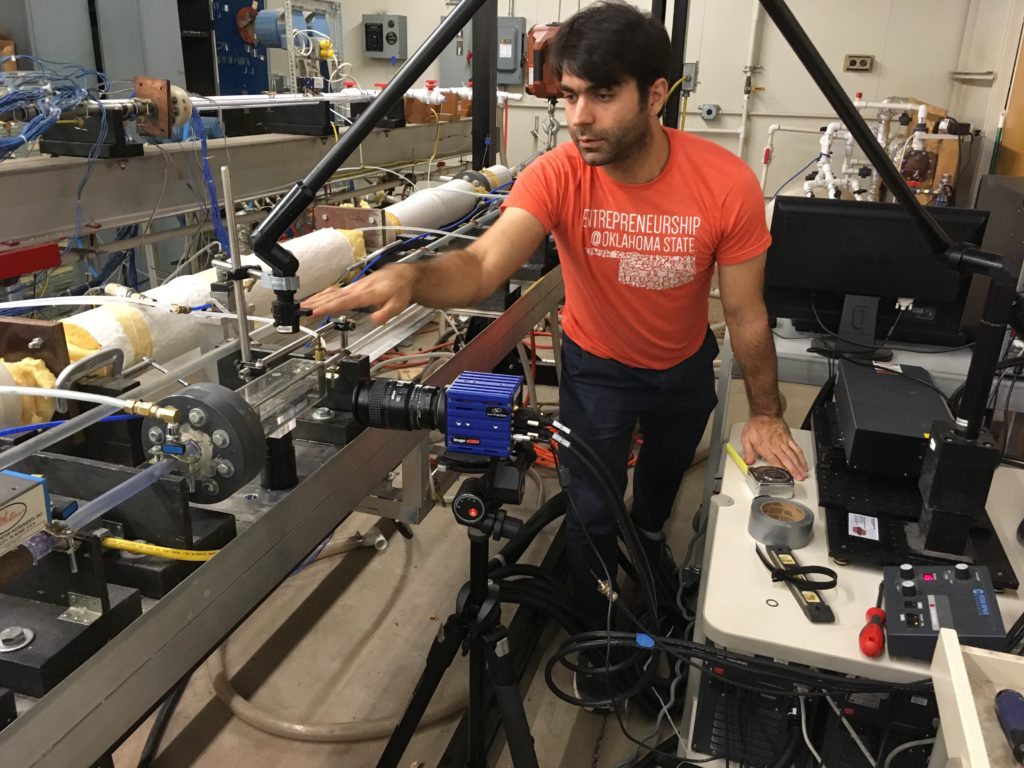

Vibrating Bubble Column

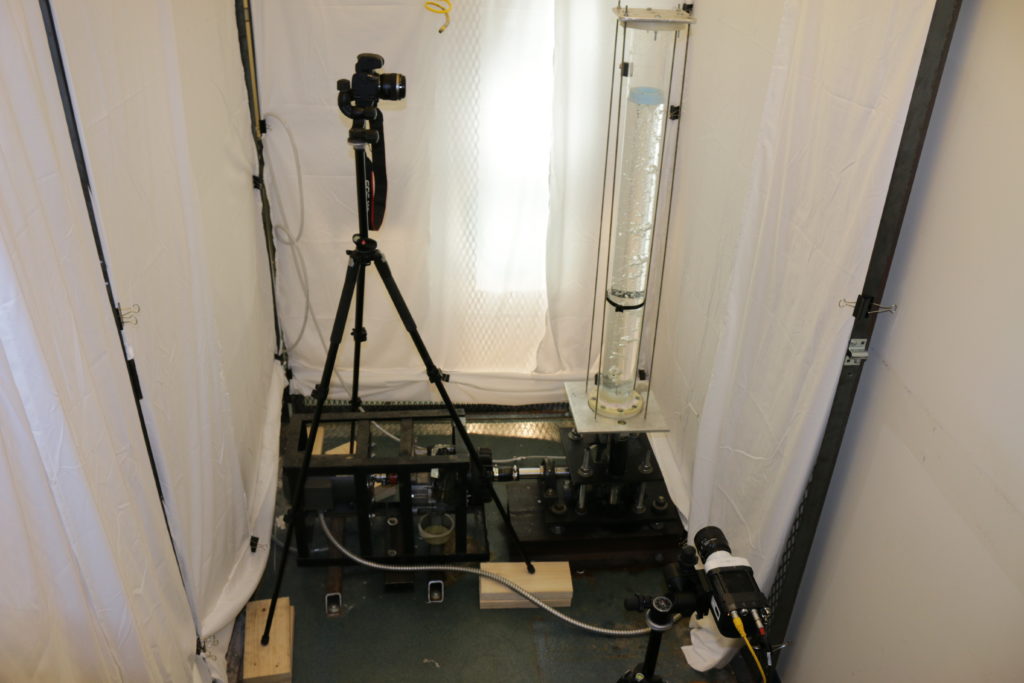

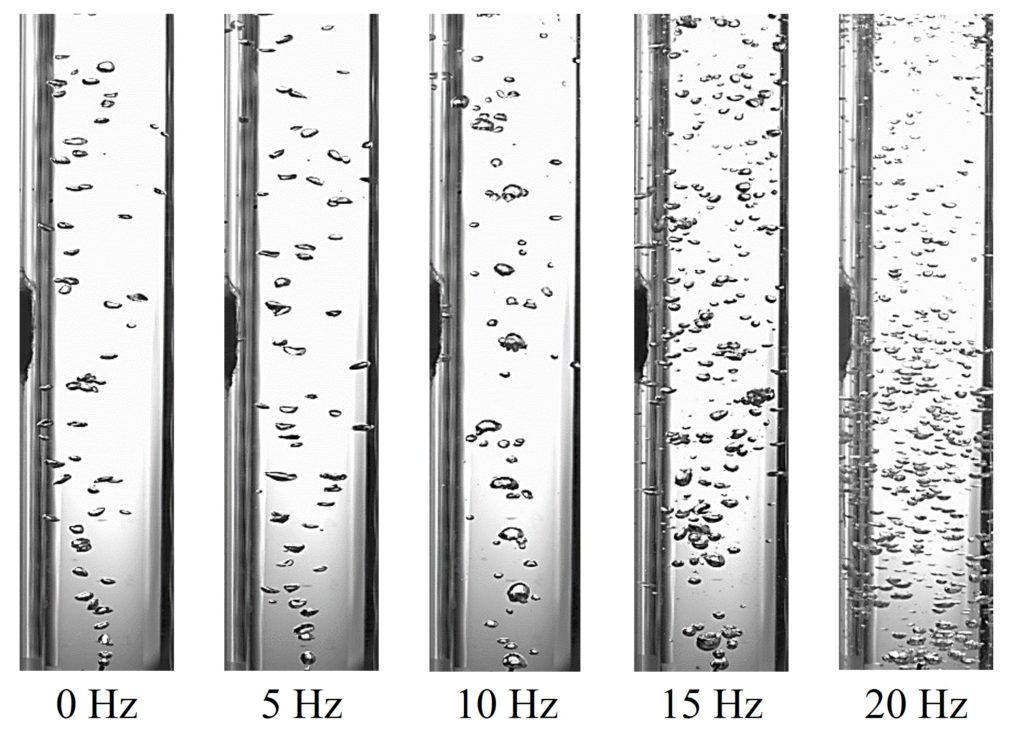

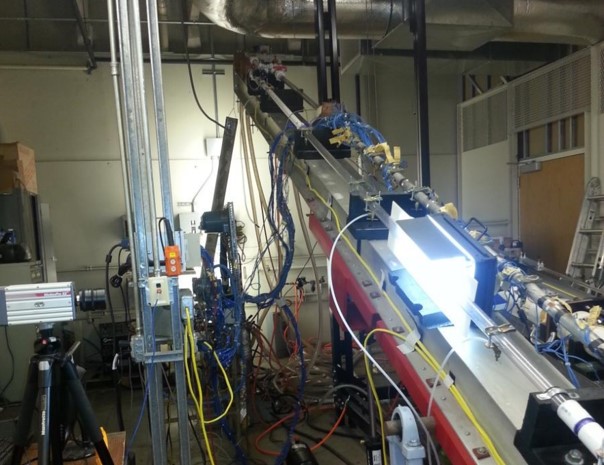

Overview

In spite of the nearly ubiquitous use of gas bubbles dispersed in liquids for natural and industrial processes, the coupling between the liquid and gas governing equations remains unknown. To date researchers use heuristic models given a specific flow pattern to approximate the mass, force, and energy interaction terms between phases (Brennen, 2005). A fundamental understanding of these relationships remains elusive in large part due to the inability to isolate single mechanism and/or replicate test conditions without inadvertently altering additional parameters. Thus there is a need for fundamental investigations that can isolate forcing mechanisms in order to determine the phase coupling relationships. The long-term goal is to develop a fundamental understanding of the physical mechanisms and the coupling between processes that determine the bubble size distribution, bubble velocity, and the resulting liquid velocity fluctuations within a buoyancy driven bubbly flow.

Select Publications

- BR Elbing†, AL Still & AJ Ghajar (2016) “Review of bubble column reactors with vibration,” Industrial & Engineering Chemistry Research, 55(2), 385-406 (doi.org/10.1021/acs.iecr.5b02535).

- S Mohagheghian & BR Elbing† (2018) “Characterization of bubble size distribution within a bubble column,” Fluids, 3(1), 13 (doi.org/10.3390/fluids3010013).

- S Mohagheghian, AL Still, BR Elbing† & AJ Ghajar (2018) “Study of bubble size, void fraction, and mass transport in a bubble column under high amplitude vibration,” ChemEngineering, 2(2), 16 (doi.org/10.3390/chemengineering2020016).